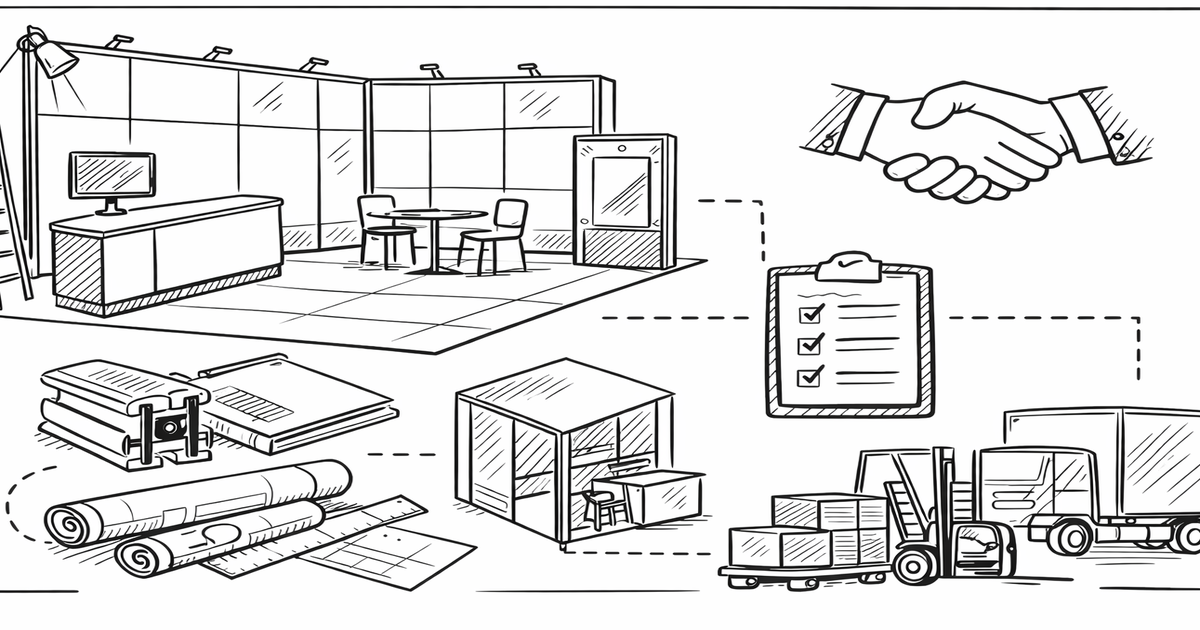

Scanex is a Danish exhibition stand builder supporting international exhibition companies that require reliable local execution in Denmark.

In cross-border exhibition projects, the design, client contact and project ownership often remain with the originating builder. Scanex performs the technical realisation — ensuring the stand is built exactly as intended.

The objective is consistency.

A stand that travels between countries must remain recognisable to returning visitors. Execution therefore follows documentation, not interpretation.

Working with Octanorm and Aluvision

Scanex works daily with Octanorm and Aluvision as modular construction systems.

Both are widely used across Europe and function as shared technical platforms between stand builders.

Because the systems are standardised, project documentation can be reused directly.

Practical effects:

- construction drawings remain valid

- mounting logic is familiar

- geometry remains identical

No conversion phase is required before production.

For international exhibition projects this significantly reduces technical clarification and scheduling risk.

Technical Continuity Across Multiple Exhibitions

Repeated exhibition stands depend on dimensional accuracy, not only graphic design.

Small deviations between builds affect perception:

- counter heights influence ergonomics

- wall alignment changes lighting behaviour

- ceiling structures alter spatial proportion

- graphic rhythm depends on exact module spacing

Using Octanorm or Aluvision with identical modular logic ensures the stand is perceived as the same installation — not a variation.

This is essential for companies exhibiting across several trade fairs annually.

OSPI Network and International Cooperation

Scanex has been part of Octanorm Service Partner International (OSPI) for more than 20 years and is the only OSPI partner in Denmark.

OSPI functions as an operational framework rather than a marketing association.

In practical terms

- drawings can be forwarded without reinterpretation

- tolerances are understood in advance

- responsibilities remain clearly separated

- installation results are predictable

Projects handled by Scanex are not limited to Octanorm-only environments.

Many partners operate primarily in Aluvision or mixed systems.

The decisive factor is technical compatibility — not exclusivity of one system.

Building Exhibition Stands in Denmark

International exhibition builders frequently require local stand construction in Denmark.

Cross-border installation teams often introduce logistical complexity:

- transport cost and timing

- venue regulations

- labour hour restrictions

- unloading windows

- hall access limitations

Using alocal exhibition stand builder reduces risk while preserving the original design.

Typical local responsibilities

- technical drawing verification

- venue coordination

- build-up and dismantling

- onsite adjustments

The originating builder keeps contact with the customer — Scanex delivers the physical stand.

Exhibitors Going Abroad

The same workflow applies when (mainly) Danish exhibitors participate internationally. Instead of transporting a full stand construction, the concept is prepared once and realised locally through partners.

Example: Naidex Birmingham

Scanex produced design and technical documentation.

A UK partner executed the installation under local conditions.

Result: A happy customer with the desired identity and function at the stand.

Planning and Technical Preparation

International exhibition reliability depends more on preparation than assembly speed.

Before build-up Scanex typically:

- reviews construction drawings

- checks venue regulations

- clarifies tolerances and materials

- prepares installation sequence

The aim is to eliminate uncertainty before installation begins.

Why Local Execution Is Used

Local execution is typically a practical decision rather than a strategic one.

Common reasons include:

- short installation windows

- transport limitations

- labour rules

- repeated events

- cost balance

The stand remains the same — only the place of assembly changes.

FAQ

-

Do you replace the original stand builder?

No.The originating company keeps the customer and project ownership. Scanexperforms local execution.

-

Do you work with both Octanorm and Aluvision?

Yes.Both systems are handled equally and often appear in mixed projects.

-

Do you coordinate with Danish venues and organisers?

Yes. Local communication and compliance checks are handled when required.

-

Can Danish exhibitors repeat the same stand abroad?

Yes. Scanex can prepare documentation for local execution through partners.

-

Is OSPI required for cooperation?

No. OSPI confirms compatibility, but projects can also be executed outside thenetwork when documentation is clear.